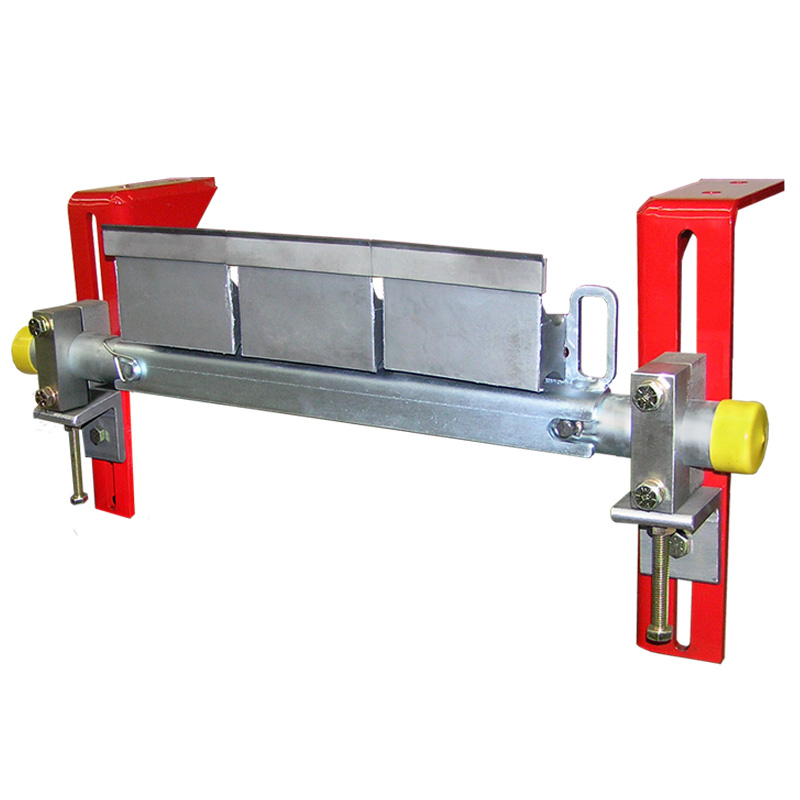

RAZOR-BACK® BELT CLEANER

-

Features & Benefits

- Maximum Belt Speed – 1000 fpm (5.0 m/sec)

- Application – Coal Fired Power Plants, Hard Rock Mining, Steel Mills, Iron Ore, Aggregate and Mineral (Phosphate, Potash, Salt) Mining.

Longwearing Abrasion Resistant Blades – available with replaceable V-Tips for vulcanized conveyor belts or C-Tips or F-Tips for conveyor belts with mechanical fasteners. Also available with Urethane and AR™ 400 blades.

Impact Absorbing Tension Cushions – each individual blade to the belt for a controlled and effective belt cleaning across the entire width of the belt.

Compact Design – allows for an installation that requires less then 9” of clearance to be installed and maintained.

Mechanical Splices? No Problem – The Razor-Back® can be installed on belts with mechanical splices, due to the laid-back wiping blade angle and impact- absorbing tensioning cushions, allowing the mechanical splices to pass without damaging the belt cleaner or the splice.

Blade Cartridge – allows for easy change out of scraper blades from either side of the conveyor

Available Tensioning Systems – Bolt-Up™, Duo-Spring™, or Spring-Shoc™

Available Optional Spray-Bar – Spray nozzle sizes can be customized for any desired spray pattern and water pressure.

Product Specifications

Razor-Back® with Spray Bar

Razor-Back® with Spray Bar is a secondary belt cleaner that uses a row of spray nozzles to spray a fine sharp stream of water at a 30° degree angle onto the conveyor belt where the carry-back material is difficult to remove. Water is applied to the belt in an overlapping spray pattern which places the particles into a fluid suspension, while moistening the belt.

The blades of the Razor-Back® with Spray Bar are then able to make consistent contact with the conveyor belt surface to remove nearly 98% or more of bulk material coarse.

เราคือผู้บริการให้คำปรึกษาและจำหน่าย ลวดเชื่อม อุปกรณ์การเชื่อมแบบครบวงจร

Copyrights © 2022 All Rights Reserved.