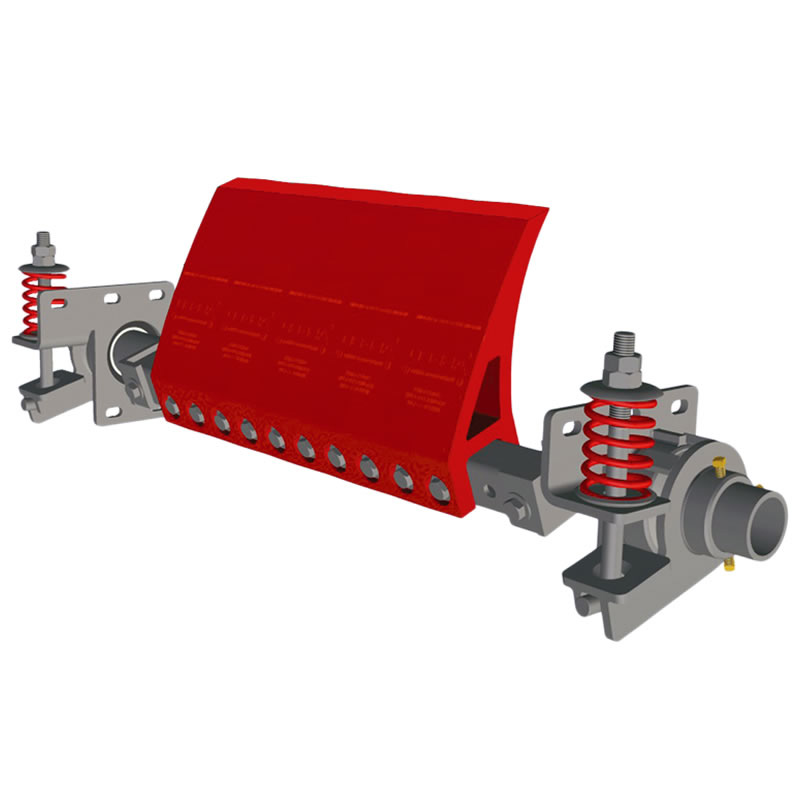

SKALPER MDX® BELT CLEANER

-

Features and Benefits

- Impact forces create a torque, rotating the blade away from the head pulley to prevent the mounting tube from bending.

- Torque cam action lever allows the blade to angle into the belt to get rid of carry-back and prevents damage from material impact or mechanical splices.

- Adjustable 6” blade segments provide coverage where it is needed most, on the belt’s material path, minimizing blade wear.

- Blades are quickly replaced with new ones by removing just 2 bolts per blade segment

- More Aggressive

- Self-Sharpening

- Less Abrasion Between Blade and Belt

- Less Chance of Blade Feathering

Extremely Rugged – Heavy-Duty structural steel, 3/8″ x 3″ dia-meter square mounting frame with a massive 14″ abrasion resistant urethane blade segments individually adjust to the imperfections in the conveyor belt cover.

Impact Torque Cam Action – offset mounting tube allows the blade to angle up and into the belt to remove carry-back and as mechanical splices come by the belt cleaner the offset cam allows the mounting tube and blades to move downward away from the belt, therefore improving the life of the belt cleaner blades while not damaging/bending the mounting tubes.

Spring-Shoc™ or Air-Shoc™ – (both are Stainless Steel) dual-tensioning systems are available depending on your bulk material handling application to provide consistent self-adjusting pressure for optimal tension against the conveyor belt.

Optional – Ceramic (XC) blade available for high speed tonnage conveyor systems.

Skalper MDX® Torque Cam Mechanism

Blade Angle

A flat pulley surface side of the blade ensures a sharp point contact and material clearance.

Available Blades

Product Specifications

Maximum Belt Speed – 1200 fpm (6.0 m/sec)

Pulley Diameter – 24″ + (600mm+)

Applications – Underground Mining, Hard Rock Mining, Oil Sands Mining,

Metals (copper/gold) Mining, Steel Mills, Iron Ore, Bulk Shipping Terminals

เราคือผู้บริการให้คำปรึกษาและจำหน่าย ลวดเชื่อม อุปกรณ์การเชื่อมแบบครบวงจร

Copyrights © 2022 All Rights Reserved.